The angular contact bearing, with its specially designed contact angle, enhances load capacity, making it suitable for high-speed and heavy-duty applications. Composed of an outer ring, inner ring, rolling elements, and a cage, it features excellent stability and long service life. It is widely used in CNC machines, automotive manufacturing, and other fields. Installation methods include back-to-back, face-to-face, tandem, and positioning installations.

I.Introduction to Angular Contact Bearings

Angular contact ball bearings feature a contact point between the steel balls and inner/outer rings, forming an angle with the radial direction. Common contact angles are 15°, 30°, and 40°, denoted by C, A, and B respectively. NSK produces a special bearing with a 25° contact angle, represented by A5. Angular contact ball bearings are mainly designed to handle large unidirectional axial loads. The larger the contact angle, the higher the load capacity. Cage materials can be steel, brass, or engineering plastics. The manufacturing process involves either stamping or turning, depending on the bearing type and application conditions. Variants include combined angular contact ball bearings, double-row angular contact ball bearings, and four-point contact ball bearings.

II.Basic Structure and Features of Angular Contact Bearings

As the name suggests, the contact angle design of angular contact bearings allows them to form a specific angle under load. This design distributes pressure, enhancing load capacity. The basic structure consists of an outer ring, inner ring, rolling elements, and a cage. The rolling elements are typically spherical balls that roll between the inner and outer rings, reducing friction and improving operational efficiency.

Key features of angular contact bearings include:

- High load capacity: The special contact angle design enables these bearings to support both radial and axial loads, making them ideal for high-speed, heavy-duty applications.

- Good stability: Angular contact bearings maintain a stable contact position during operation, reducing vibration and noise. This enhances the smooth operation of machinery.

- Long service life: Made from high-quality materials and precision manufacturing processes, angular contact bearings offer a long service life, reducing maintenance costs and improving overall equipment efficiency.

III. Application Fields of Angular Contact Bearings

Angular contact bearings are widely used in various machinery, especially in applications requiring high speed, heavy loads, and precision. Examples include CNC machines, precision instruments, automotive manufacturing, and aerospace. These industries rely on the support of angular contact bearings to ensure smooth and efficient operation.

IV. Installation Methods of Angular Contact Bearings

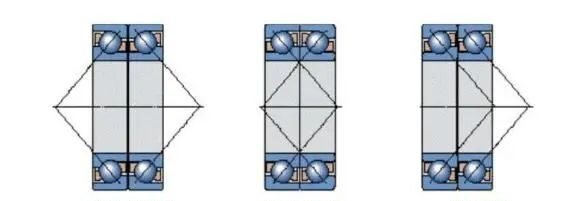

There are four main installation methods for angular contact bearings: back-to-back, face-to-face, tandem, and positioning. The choice of method depends on the working conditions and specific application needs.

- Back-to-back installation: This method places two angular contact ball bearings with their backs facing each other. It is ideal for handling large axial and impact loads. In this configuration, the contact angles automatically adjust to accommodate different operating conditions.

- Face-to-face installation: Here, two angular contact ball bearings are installed facing each other. This setup is suitable for lighter axial and impact loads. Compared to back-to-back installation, face-to-face installation allows for larger internal clearance, reducing stiffness and extending bearing life. However, the ability to adjust contact angles is limited, requiring more precise axial alignment and positioning.

- Tandem installation: Multiple angular contact bearings are arranged in a series. This method is best for handling large radial and impact loads. Tandem installation requires precise axial alignment; otherwise, misalignment can lead to bearing wear and reduced efficiency.

Contact us for expert support in custom machined parts. We’re dedicated to delivering high quality, precision, and quick turnaround for your projects.