CNC Milling: A Guide for Advanced Beginners with Applications in Prototyping

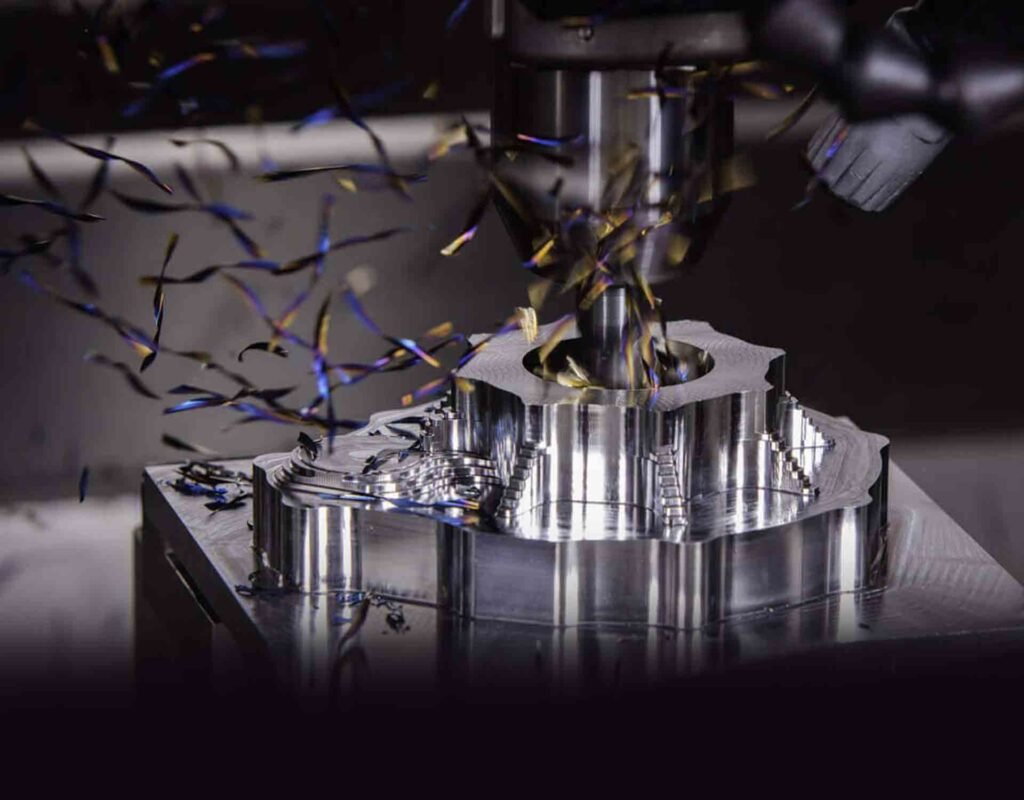

CNC milling is one of the most common and effective methods in professional prototyping. It can easily handle small to medium batch production, and in some cases, even larger volumes. Its flexibility and versatility make it a top choice for designers and engineers alike. However, like any manufacturing process, the more familiar designers are with […]

CNC Milling: A Guide for Advanced Beginners with Applications in Prototyping Read More »